- APN Home›

- APN Journal›

- Partner Success Stories›

- APN Blog›

- APN YouTube Channel›

- Join the APN

Amazon Prime Air’s Drone Takes Flight with AWS and Siemens

Siemens is an AWS Advanced Technology Partner

About Prime Air

Executive Summary

Amazon Prime Air developed a working drone design by running simulations using Siemens’ Simcenter STAR-CCM+ with high performance computing (HPC) on Amazon Web Services (AWS). The on-demand access to nearly unlimited infrastructure and fast networking for scalable HPC on AWS ensured that the project stuck to the timeframe. Simcenter STAR-CCM+ on AWS helped Prime Air streamline its engineering workflows, which resulted in additional efficiency gains.

Challenge

Amazon Prime Air needed to design and build a drone for unmanned deliveries. Simulating the aerodynamics required two main components. First, it needed a computational fluid dynamics (CFD) solution that could run individual and batches of simulations. Second, it needed HPC infrastructure that offered a large, on-demand capacity of instances and ran on a fast, high-bandwidth network to support the workstreams.

Solution

Prime Air chose Siemens’ Simcenter STAR-CCM+, part of the Simcenter portfolio, as its multiphysics CFD solution for aerodynamic design. Simcenter STAR-CCM+ is built for parallel efficiency, which allowed Prime Air to speed up its CFD simulations by running them on a large number of cores. Additionally, Simcenter STAR-CCM+ allowed Prime Air to streamline its engineering simulation workflow. The breadth of HPC solutions available from AWS provided the flexibility needed to deliver against tight timelines. It used AWS ParallelCluster, the AWS-supported open source cluster management tool, to manage the deployment of Amazon Elastic Compute Cloud (Amazon EC2) compute optimized instances.

Benefits

Using Simcenter STAR-CCM+ on AWS enabled Prime Air engineers to characterize the aerodynamics of aircraft across its full flight envelope, a simulation campaign that consisted of thousands of different operating conditions and added up to more than 30 million hours of AWS compute time. Additional analysis helped them identify critical flight conditions that they examined further in real time through remote visualization and post-processing, eliminating the need to transfer large data sets and own expensive dedicated workstations.

The HPC services on AWS made it easy for them to scale to a large number of cores and access on-demand compute power for analysis—without getting stuck in long queues. They were also able to scale down the instances after running simulations. As a result, Prime Air confidently moved to a working drone design in a compressed timeline.

Prime Air Rises to the Challenge Using CFD on AWS

Prime Air’s goal is to deliver packages to customers that weigh five pounds or less in under 30 minutes using drones. The Prime Air team designed and built its own drone using CFD, a branch of fluid dynamics that uses numerical analysis and data to solve problems of how fluids, like air, move under different conditions around an aircraft.

Prime Air chose Siemens’ Simcenter STAR-CCM+ as its complete multiphysics solution for CFD. Simcenter STAR-CCM+ is built for parallel efficiency, which allowed Prime Air to speed up its simulations by running them on a large number of cores. Additionally, Simcenter STAR-CCM+ Application Programming Interfaces (API) allowed Prime Air to automate and streamline its engineering workflow.

Building an aircraft using CFD involves digitally predicting aerodynamic performance. Thousands of such CFD simulations are typically needed to generate an aerodynamic database (ADB) to ensure performance across all flight conditions and develop an aircraft control system. The scale and speed of these simulations necessitates HPC resources. However, many on-premise datacenters have capacity and availability constraints on HPC resources that lead to long queues. Engineers must wait their turn and only use the resources allocated to them, which doesn’t leave them much room to modify the test plan once their simulations have been launched.

Our focus should not be on designing and developing HPC infrastructure, but on designing and developing aircraft. By choosing Simcenter STAR-CCM+ on AWS for our workflow, we were able to put the focus where it belongs.

Vedran Coralic

Senior Applied Scientist, Amazon Prime AirEngineers Access HPC Resources On-Demand with AWS Cloud Services

Prime Air chose to deploy Simcenter STAR-CCM+ on AWS in order to scale compute power up and down as needed. With AWS, engineers can run simulations without having to wait in a queue or pay for excess capacity. AWS offers a large breadth of HPC services that give customers flexibility when it comes to choosing how best to support their application and deliver the time-to-results their engineers need. Prime Air chose these ready-to-use, nearly unlimited, scalable HPC services on AWS to help it get started fast and focus on what it does best.

Running on the cloud allows engineers to go as fast as they want by using as many cores as they need whenever they need them—without incurring excessive costs or slowing down others who need access at the same time.

“On AWS, we can run when we want, with however many cores we want, and get results in the same day. We’re not bottlenecked by capacity,” said Vedran Coralic, Senior Applied Scientist at Prime Air. “And we don’t have to think of everything we’ll need from a simulation ahead of run time. We can always pull it up on AWS after it has been completed and query the flow in real time. By running Simcenter STAR-CCM+ on AWS, my team can move as fast as the program needs it to.”

Improved HPC Management and Performance Enables Greater Innovation

Learn More

Prime Air designed its environment for running CFD using AWS ParallelCluster, the open source cluster management tool. AWS ParallelCluster simplifies the deployment of launching the Siemens’ Simcenter STAR-CCM+ environment on AWS by using a configuration file to provision all resources in the HPC environment (e.g. virtual private cloud, shared file system, etc.). It supports various popular HPC job schedulers like Slurm, which manage jobs and scale clusters up and down in response to the workload.

To achieve the speeds needed for its CFD simulations, Prime Air provisioned clusters with Amazon EC2 compute optimized instances, using the latest in the market at the time, to optimally support its HPC workloads. Given the sheer volume capacity available through AWS, Coralic hypothesized that they could probably run all of their ADB simulations in one shot on AWS. “Running Simcenter STAR-CCM+ on AWS lets us evaluate new ideas quickly and spend more time investigating results and less time waiting for them,” said Coralic.

With the recent launch of Amazon EC2 C5n instances, the Prime Air team tested AWS ParallelCluster deployments of C5n.18xlarge Intel instances with Elastic Fabric Adapter (EFA). EFA is a network interface custom built by AWS that provides operating system (OS) bypass capabilities to Amazon EC2 instances, thereby enabling customers to run applications with low-latency, high-throughput inter-node communications at scale.

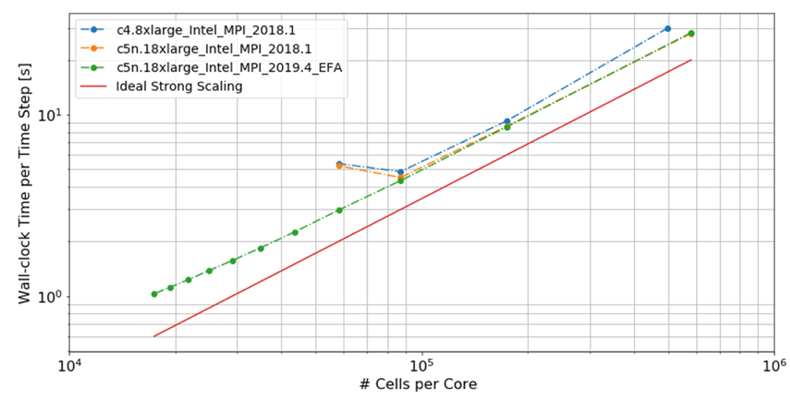

“Based on initial benchmarks, we believe that moving to C5n instances with EFA for the next ADB will allow us to complete it two times faster,” explained Coralic, “because we can scale out to twice as many cores without degrading computational efficiency or substantially increasing the compute cost.”

Appendix:

Figure 1: The plot shows that Prime Air will be able to scale its future CFD simulations to 50,000 cells/core and beyond, with negligible loss in computational efficiency. This is made possible by EFA, which is supported by the newer generation compute instances, C5n, as shown by the green curve. Without EFA, Prime Air was only able to scale down to 100,000 cells/core as depicted by the blue and orange curves.

About Siemens

Publish date:

November 2020