Industrial Internet of Things

Ottieni informazioni più approfondite dai tuoi dati e crea applicazioni industriali complesse e scalabili utilizzando AWS IoT.

Industrial IoT (IIoT) accorpa macchine industriali, cloud computing, analisi e persone per migliorare la prestazione e la produttività dei processi industriali. Con IIoT, le aziende industriali possono digitalizzare processi, trasformare modelli aziendali e migliorare le prestazioni e la produttività, il tutto riducendo gli sprechi. Queste aziende ad alta intensità di risorse che operano in una serie di settori come la produzione, l'energia, l'agricoltura, i trasporti e i servizi pubblici, stanno lavorando a progetti IoT che connettono miliardi di dispositivi e generano valore in una varietà di casi d'uso includendo qualità predittiva e analisi di manutenzione, monitoraggio delle condizioni degli asset e ottimizzazione dei processi.

Una tipica struttura industriale ha migliaia di sensori che generano dati. Con l'IIoT, ad esempio, i produttori possono combinare i dati delle macchine di una singola linea, di una fabbrica o di una rete di siti, come gli impianti di produzione, le strutture di assemblaggio e le raffinerie, per migliorare proattivamente le prestazioni identificando potenziali colli di bottiglia, guasti, lacune nei processi di produzione e problemi di qualità prima che si verifichino. La combinazione dei dati provenienti da una rete di siti può anche tradursi in un controllo più efficiente del flusso di materiali, in un rilevamento precoce e nell'identificazione ed eliminazione di colli di bottiglia nella produzione o nella fornitura, nonché in un funzionamento ottimizzato dei macchinari e delle attrezzature in tutte le strutture.

Casi d'uso IoT industriale

Qualità predittiva

L'analisi predittiva della qualità estrae informazioni fruibili da fonti di dati industriali come apparecchiature di produzione, condizioni ambientali e osservazioni umane per ottimizzare la qualità della produzione in fabbrica. Grazie ad AWS IoT, i produttori industriali possono creare modelli di qualità predittivi che aiutano a produrre prodotti si qualità superiore. Prodotti di qualità superiore aumentano la soddisfazione del cliente e riducono il richiamo dei prodotti.

Monitoraggio delle condizioni degli asset

Il monitoraggio delle condizioni degli asset rileva lo stato delle tue macchine e attrezzature per determinare le prestazioni delle risorse. Con AWS IoT, puoi acquisire tutti i dati IoT, ad esempio temperatura, vibrazione e codici di errore che indicano se l'apparecchiatura funziona in modo ottimale. Con una maggiore visibilità, puoi massimizzare l'utilizzo e l'investimento delle risorse.

Manutenzione predittiva

L'analisi della manutenzione predittiva rileva lo stato delle attrezzature industriali per identificare potenziali guasti prima che incidano sulla produzione, con conseguente aumento della durata delle attrezzature, della sicurezza degli operai e dell'ottimizzazione della catena di distribuzione. Con AWS IoT, puoi monitorare e desumere continuamente lo stato, l'integrità e le prestazioni delle apparecchiature in modo da rilevare i problemi in tempo reale.

Casi di studio

Volkswagen Group utilizza AWS IoT per aumentare l'efficienza e i tempi di attività degli stabilimenti, migliorare la flessibilità produttiva e aumentare la qualità dei veicoli.

Pentair utilizza AWS IoT per migliorare i processi di filtraggio della birra e aumentare le prestazioni del 10%.

Woodside Energy sfrutta AWS IoT per ridurre il tempo necessario per la distribuzione di nuovi algoritmi di analisi da 3-6 mesi a poche settimane e a volte persino giorni.

Deutsche Bahn utilizza AWS IoT per ottenere nuove informazioni utili a garantire l'efficienza operativa della loro flotta ferroviaria.

Perché optare per AWS IoT per le applicazioni industriali

Grazie alla più ampia e avanzata funzionalità dai dispositivi al cloud, AWS IoT aiuta clienti come Volkswagen, Yanmar, Vantage Power, British Gas, SolarNow, CAF e Honeywell a migliorare le prestazioni e la produttività dei processi industriali. Questi clienti si affidano ad AWS IoT per creare applicazioni che risolvano i problemi che incontrano i clienti industriali e generare nuovo valore aziendale attraverso analisi di qualità predittiva, monitoraggio delle condizioni degli asset, analisi di manutenzione predittiva e ottimizzazione dei processi.

Soluzione completa per IoT industriale

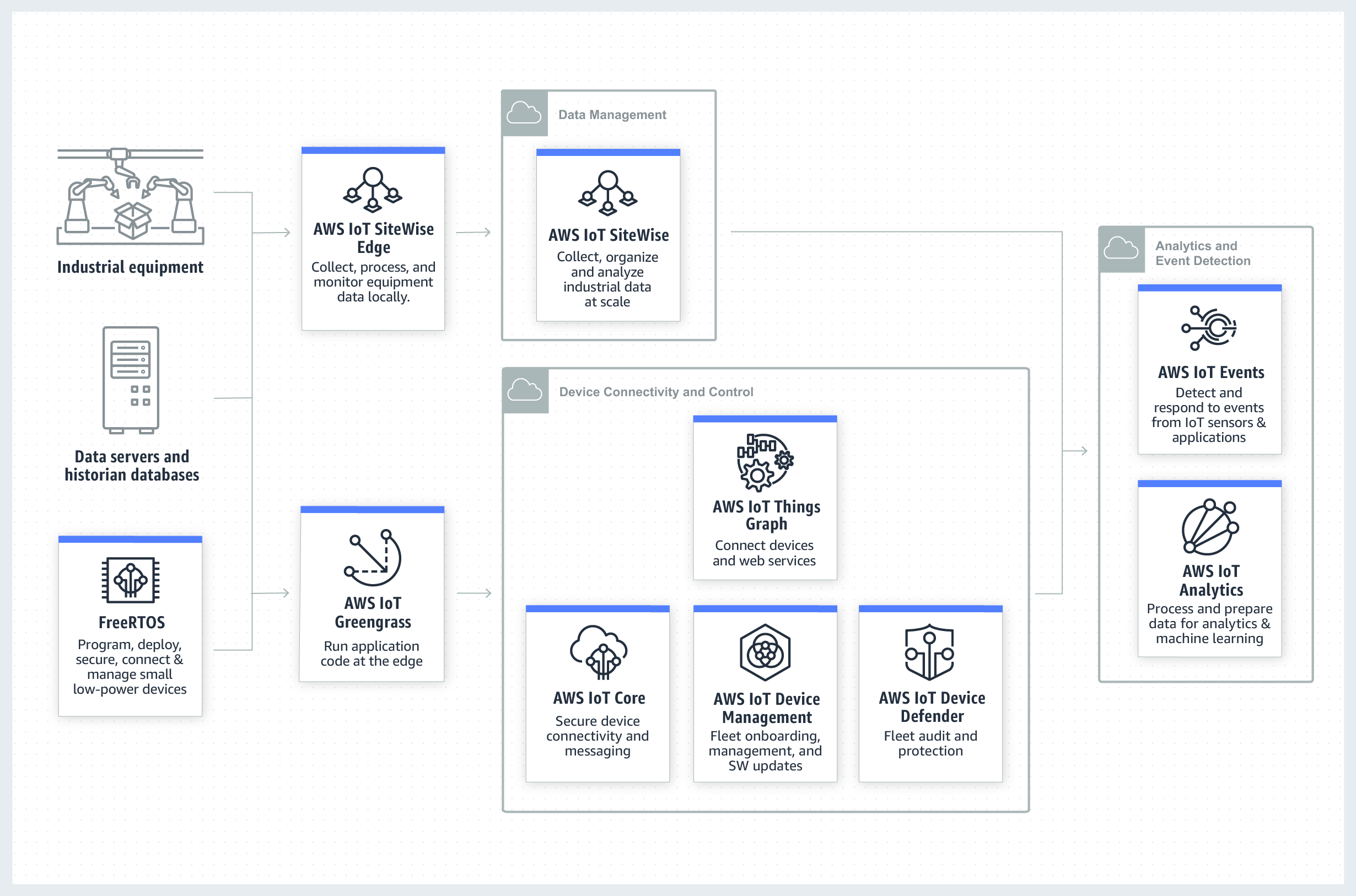

AWS IoT è costituito da una serie di servizi completamente gestiti che semplificano la distribuzione e la gestione di una soluzione completa di IoT industriale.

Raccogli, archivia e analizza dati di dispositivi

AWS IoT offre una serie di servizi progettati in maniera specifica per semplificare la raccolta, l'archiviazione e l'analisi di dati di dispositivi anche nel più rumoroso e inaffidabile degli ambienti.

Elevata scalabilità

AWS IoT aiuta i clienti a scalare le loro applicazioni di IoT industriale fino a milioni di dispositivi.

Sicurezza progettata per IoT

AWS IoT semplifica ai clienti la protezione della flotta di dispositivi su vasta scala grazie ad autenticazione e autorizzazione integrate dei dispositivi per mantenere sicuri dati e dispositivi IoT industriale.

Servizi AWS IoT per applicazioni industriali

Esplora le risorse di IoT industriale

Percorso alla produzione moderna con AWS

Scopri come i clienti di produzione stanno utilizzando AWS per sfruttare le nuove opportunità tecnologiche e aziendali, liberando i dati industriali intrappolati.

Jumpstart Industry 4.0 con AWS Connected Factory Solution

Un’offerta dedicata da AWS e i partner per sbloccare i dati dalle attrezzature/PLC e dai dati storici per ottimizzare le operazioni, migliorare la produttività e la disponibilità.

Principali casi d'uso per applicazioni Industrial IoT

Scopri come AWS IoT aiuta le aziende industriali a superare le difficoltà per raggiungere obiettivi aziendali tramite casi d'uso comuni che includono qualità predittiva, manutenzione predittiva e monitoraggio delle condizioni degli asset.

eBook sulla manutenzione predittiva dell'IoT industriale di AWS

Scopri i vantaggi e le sfide della manutenzione predittiva basata sull'IoT industriale (IIoT) e come AWS e le soluzioni dei partner per la manutenzione predittiva basata su IIoT generano risultati aziendale di valore per il settore.

Creare una soluzione di IoT industriale (IIoT) end-to-end con AWS IoT

I dati degli stabilimenti industriali restano spesso inutilizzati perché bloccati in dispositivi e attrezzature in locale, come nel caso dei dati storici proprietari. Con AWS IoT hai la possibilità di creare soluzioni di IoT industriale (IIoT) sicure, economiche e affidabili che acquisiscono flussi di dati in tempo reale da centinaia di stabilimenti industriali contenenti sia asset di dati che di macchinari.

Coordina l’Overall Equipment Effectiveness (OEE) attraverso le tue strutture aziendali

Ottenere l'efficienza complessiva delle attrezzature (OEE, Overall Equipment Effectiveness) delle apparecchiature industriali è complicato, poiché i dati sono spesso bloccati in archivi dati proprietari in locale e, in genere, richiedono degli esperti specializzati per essere recuperati e sistemati in un formato che sia utile per la ricerca e l'analisi. AWS IoT SiteWise semplifica la raccolta e l'organizzazione di dati di apparecchiature industriali.

Volkswagen takes production to the cloud (46:25)

Scopri come Volkswagen e AWS stanno implementando la piattaforma di produzione digitale (DPP, digital production platform) all'interno dell'Industrial Cloud di Volkswagen per trasformare i processi manifatturieri e logistici dell'azienda, aumentare i tempi di attività e l'efficienza degli stabilimenti, migliorare la flessibilità produttiva e la qualità dei veicoli.

Driving operational performance across industrial facilities with AWS (49:57)

Scopri come AWS IoT può sbloccare i tuoi dati di tecnologia operativa (OT, Operational Technology) e aiutarti a monitorare le operazioni nelle diverse strutture, elaborare velocemente parametri di comuni prestazioni industriali e creare applicazioni che analizzino i dati di apparecchiature industriali per evitare costosi problemi legati alle attrezzature e ridurre le interruzioni nella produzione.

Digital transformation and IoT monetization (54:17)

AWS IoT viene distribuito su vasta scala in settori produttivi di tutto il mondo, ma quali sono i veri risultati aziendali? In questa sessione, analizziamo nel dettaglio come alcuni clienti stanno monetizzando le loro soluzioni IoT create in AWS.

Ulteriori informazioni su AWS IoT