AWS IoT SiteWise - Kumpulkan, Atur, dan Analisis Data dari Peralatan Industri dalam Skala Besar (2:10)

Mengapa memilih AWS IoT SiteWise?

AWS IoT SiteWise merupakan sebuah layanan terkelola yang memudahkan dalam mengumpulkan, menyimpan, mengatur, dan memantau data dari peralatan industri dalam skala besar untuk membantu Anda mengambil keputusan yang lebih baik dan didukung data. Anda dapat menggunakan AWS IoT SiteWise untuk memantau operasional di seluruh fasilitas, melakukan komputasi metrik performa industri umum dengan cepat, dan membuat berbagai aplikasi yang menganalisis data peralatan industri untuk mencegah masalah peralatan yang mahal dan mengurangi kesenjangan dalam produksi.

Mengapa memilih AWS IoT SiteWise?

AWS IoT SiteWise merupakan sebuah layanan terkelola yang memudahkan dalam mengumpulkan, menyimpan, mengatur, dan memantau data dari peralatan industri dalam skala besar untuk membantu Anda mengambil keputusan yang lebih baik dan didukung data. Anda dapat menggunakan AWS IoT SiteWise untuk memantau operasional di seluruh fasilitas, melakukan komputasi metrik performa industri umum dengan cepat, dan membuat berbagai aplikasi yang menganalisis data peralatan industri untuk mencegah masalah peralatan yang mahal dan mengurangi kesenjangan dalam produksi.

Keuntungan AWS IoT SiteWise

AWS IoT SiteWise memberikan repositori terpadu untuk data operasional aktif dan historis dari peralatan, mesin, serta sistem warisan Anda.

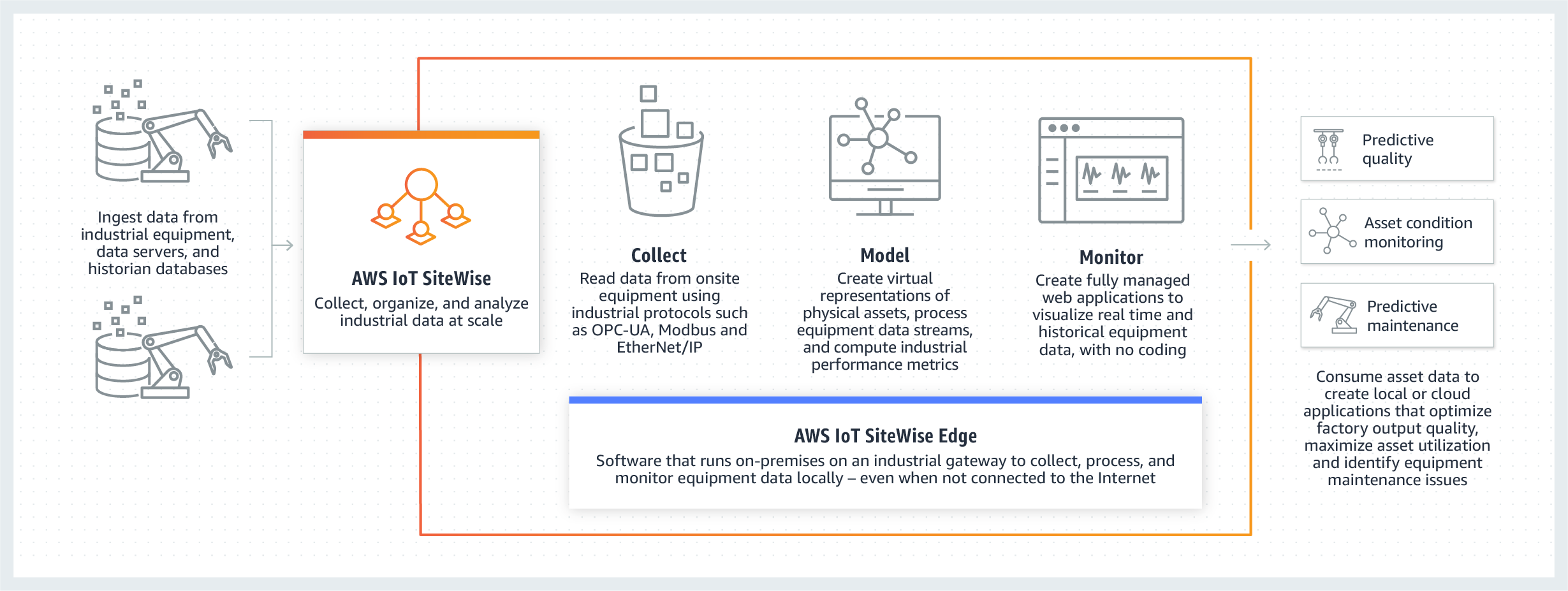

Cara kerja

AWS IoT SiteWise merupakan layanan terkelola yang menyederhanakan pengumpulan, pengaturan, dan analisis data peralatan industri.