Industrial Internet of Things

Uncover deeper insights from your data and build rich and scalable industrial applications using AWS IoT.

Industrial IoT (IIoT) brings machines, cloud computing, analytics, and people together to improve the performance and productivity of industrial processes. With IIoT, industrial companies can digitize processes, transform business models, and improve performance and productivity, while decreasing waste. These asset intensive companies operating in a range of industries such as manufacturing, energy, agriculture, transportation and utilities, are working on IoT projects that connect billions of devices and deliver value across a variety of use cases including predictive quality and maintenance analytics, asset condition monitoring, and process optimization.

A typical industrial facility has thousands of sensors generating data. With IIoT, manufacturers, for example, can combine machine data from a single line, factory, or a network of sites, such as manufacturing plants, assembly facilities, and refineries, to proactively improve performance by identifying potential bottlenecks, failures, gaps in production processes, and quality issues before they happen. Combining data from a network of sites can also result in a more efficient control of material flow, early detection and identification and elimination of production or supply bottlenecks, and the optimized operation of machinery and equipment in all facilities.

Industrial IoT Use Cases

Predictive Quality

Predictive quality analytics extracts actionable insights from industrial data sources such as manufacturing equipment, environmental conditions, and human observations to optimize the quality of factory output. Using AWS IoT, industrial manufacturers can build predictive quality models which help them build better products. Higher quality products increase customer satisfaction and reduce product recalls.

Asset Condition Monitoring

Asset condition monitoring captures the state of your machines and equipment to determine asset performance. With AWS IoT, you can capture all IoT data, such as temperature, vibration, and error codes that indicate if equipment is performing optimally. With increased visibility, you can maximize the utilization and investment of your asset.

Predictive Maintenance

Predictive maintenance analytics captures the state of industrial equipment to identify potential breakdowns before they impact production, resulting in an increase in equipment lifespan, worker safety, and the supply chain optimization. With AWS IoT, you can continuously monitor and infer equipment status, health, and performance to detect issues in real-time.

Case Studies

Volkswagen Group uses AWS IoT to increase plant efficiency and uptime, improve production flexibility, and increase vehicle quality.

Pentair uses AWS IoT to improve beer filtration processes and boost performance by 10%.

Woodside Energy leverages AWS IoT to expedite delivery of new analytics algorithms from 3-6 months to a matter of weeks and sometimes even days.

Deutsche Bahn uses AWS IoT to gain new insights to achieve operational efficiency for their rail fleet.

Why AWS IoT for Industrial Applications

With the broadest and deepest functionality from the device to the cloud, AWS IoT helps customers, such as Volkswagen, Yanmar, Vantage Power, British Gas, SolarNow, CAF, and Honeywell, improve the performance and productivity of industrial processes. These customers rely on AWS IoT to build applications that address the top challenges facing industrial customers to uncover new business value through predictive quality analytics, asset condition monitoring, predictive maintenance analytics, and process optimization.

Complete solution for Industrial IoT

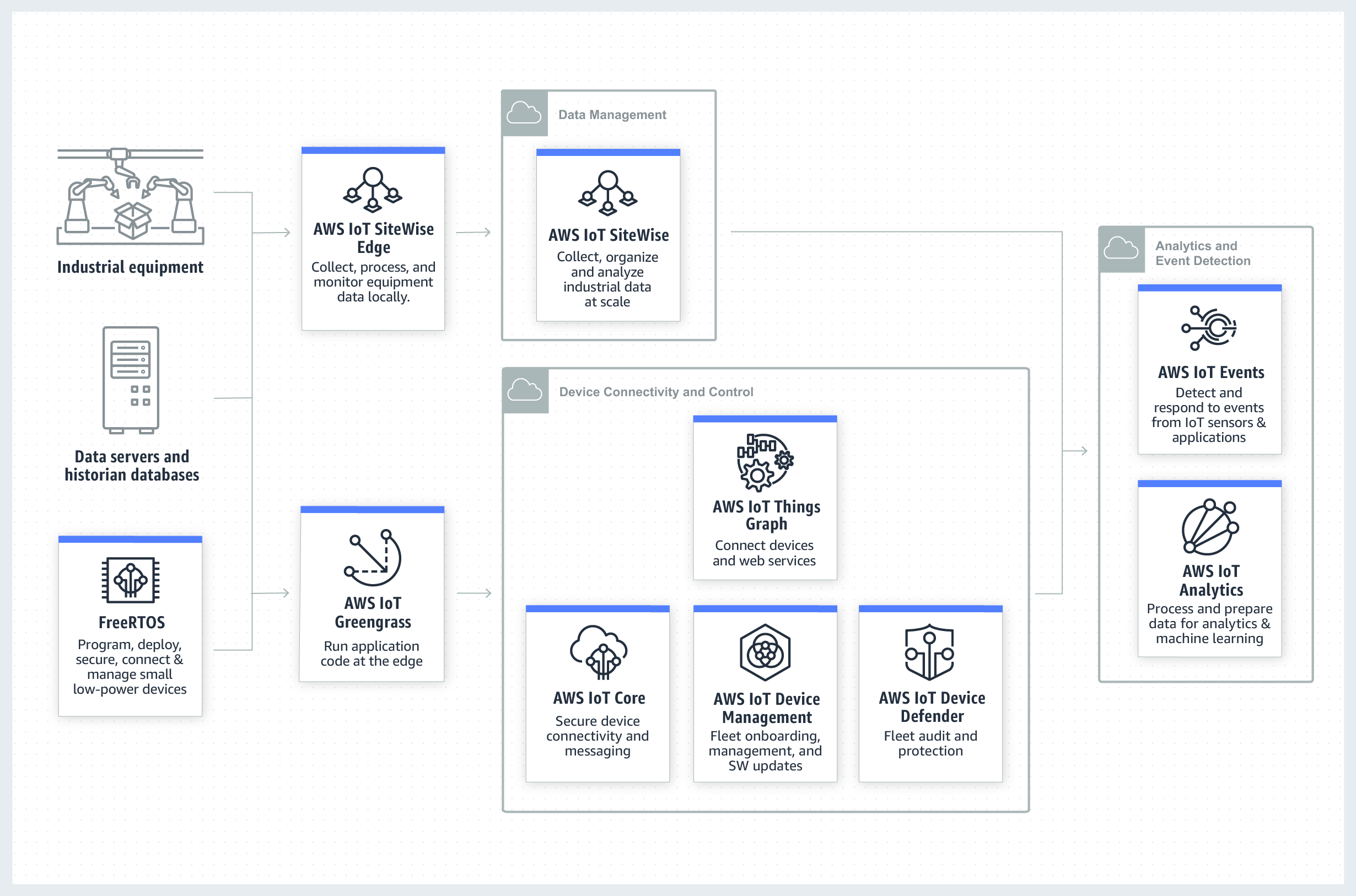

AWS IoT is a set of fully managed services that make it easy to deploy and manage a complete industrial IoT solution.

Collect, store, and analyze device data

AWS IoT provides a range of services specifically designed to make it easy to collect, store, and analyze device data even in noisy, unreliable environments.

Massively Scalable

AWS IoT helps customers scale their industrial IoT applications up to millions of devices.

Security Designed for IoT

AWS IoT makes it easy for customers to secure device fleets at scale with built-in device authentication and authorization to keep IIoT data and devices protected.

AWS IoT Services for Industrial Applications

Explore Industrial IoT Resources

The journey to modern manufacturing with AWS

Learn how manufacturing customers are using AWS to take advantage of new technology and business opportunities by unlocking their trapped industrial data.

Jumpstart Industry 4.0 with AWS Connected Factory Solution

A purpose-built offering from AWS and partners to unlock data from equipment/PLCs and Historians to optimize operations, improve productivity, and availability.

Top Use cases for Industrial IoT applications

Learn how AWS IoT helps industrial companies overcome challenges to attain business goals through common use cases including predictive quality, predictive maintenance, and asset condition monitoring.

AWS Industrial IoT Predictive Maintenance eBook

Discover the benefits and challenges of Industrial IoT (IIoT) enabled predictive maintenance, and how AWS and partner solutions for IIoT-enabled predictive maintenance deliver valuable business outcomes to industry.

Building an End-to-End Industrial IoT (IIoT) Solution with AWS IoT

Data from industrial sites is often untapped because it's locked into on-premises devices and equipment such as in proprietary historians. With AWS IoT you have the ability to build secure, cost-effective, and reliable Industrial IoT (IIoT) solutions that ingest real-time streaming data from hundreds of industrial sites containing both data assets and machine assets.

Driving Overall Equipment Effectiveness (OEE) Across Your Industrial Facilities

Driving Overall Equipment Effectiveness (OEE) from industrial equipment is difficult because data is often locked into proprietary on-premises data stores and typically requires specialized expertise to retrieve it and put it in a format that is useful for searching and analysis. AWS IoT SiteWise makes it easy to collect and organize data from industrial equipment.

Volkswagen takes production to the cloud (46:25)

Learn how Volkswagen and AWS are implementing the digital production platform (DPP) within the VW Industrial Cloud to transform the company’s manufacturing and logistics processes, increase plant efficiency and uptime, improve production flexibility, and improve vehicle quality.

Driving operational performance across industrial facilities with AWS (49:57)

Learn how AWS IoT can unlock your Operational Technology (OT) data and help you monitor operations across facilities, quickly compute common industrial performance metrics, and create applications that analyze industrial equipment data to prevent costly equipment issues and reduce gaps in production.

Digital transformation and IoT monetization (54:17)

AWS IoT is deployed at scale across industries around the globe—but what's the business outcome behind the buzz? In this session, we dive deep into how some customers are monetizing their IoT solutions built on AWS.

Learn more about AWS IoT