AWS IoT SiteWise - Collect, Organize, and Analyze Data from Industrial Equipment at Scale (2:10)

Why AWS IoT SiteWise?

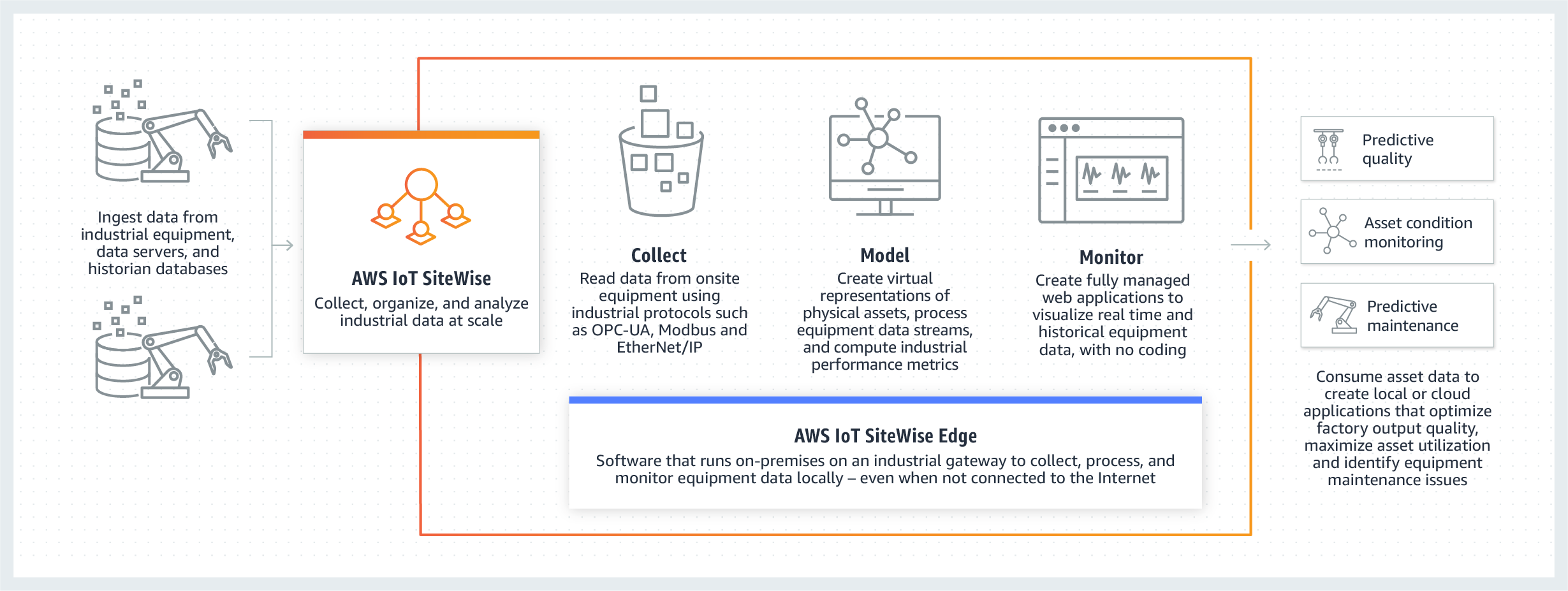

AWS IoT SiteWise is a managed service that makes it easy to collect, store, organize and monitor data from industrial equipment at scale to help you make better, data-driven decisions. You can use AWS IoT SiteWise to monitor operations across facilities, quickly compute common industrial performance metrics, and create applications that analyze industrial equipment data to prevent costly equipment issues and reduce gaps in production.

Why AWS IoT SiteWise?

AWS IoT SiteWise is a managed service that makes it easy to collect, store, organize and monitor data from industrial equipment at scale to help you make better, data-driven decisions. You can use AWS IoT SiteWise to monitor operations across facilities, quickly compute common industrial performance metrics, and create applications that analyze industrial equipment data to prevent costly equipment issues and reduce gaps in production.

Benefits of AWS IoT SiteWise

AWS IoT SiteWise delivers a unified repository of live and historical operational data from your equipment, machines, and legacy systems.

How it works

AWS IoT SiteWise is a managed service that simplifies collecting, organizing, and analyzing industrial equipment data.